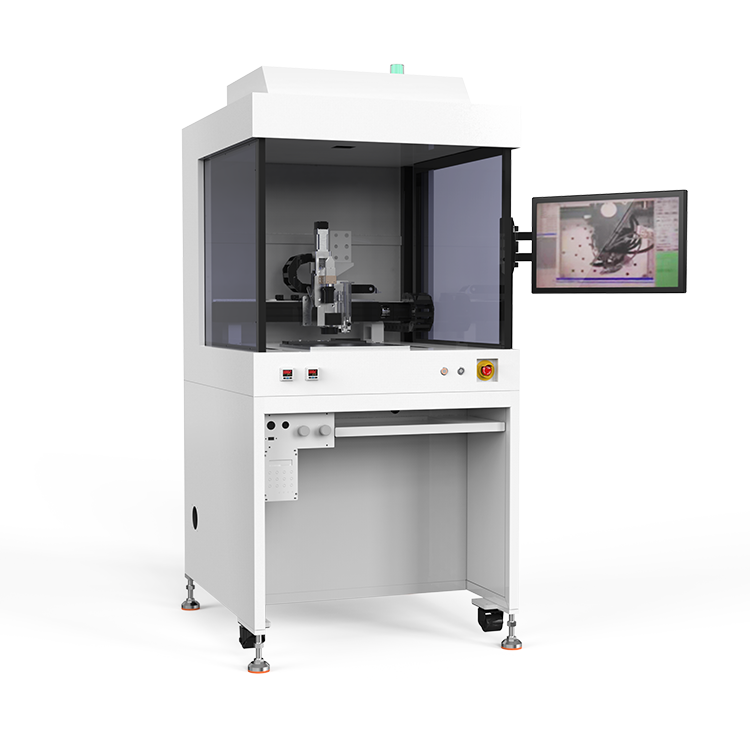

Dual visual off-line intelligent dispensing machine

Product Description

Dual visual offline intelligent dispensing machine

Dual visual Dispensing Machine, full-area visual positioning system, high intelligence, simple operation, high dispensing UPH, and no need for precision carriers.

Dual visual offline intelligent dispensing machine, combined with full-area visual positioning system and high-precision visual positioning system, can achieve high-precision, high-speed, and high-repeat dispensing operations. Can be used for underfill, cavity filling, parts coating, bonding protection, etc., widely used in semiconductor packaging, mobile phone screen modules,CCM (miniature camera module), VCM (voice coil motor), fingerprint modules, optical lenses And other precision dispensing occasions in the assembly process of small precision parts.

Features and advantages

1. Large-scale visual positioning in the whole area + high-precision visual positioning.

2. The product can be placed at 360°, and can be placed arbitrarily without jigs, intelligently identifying and positioning and automatically planning the dispensing path.

3. Automatic identification of defective products, automatic screening and dispensing of products.

4. Automatically identify the product type and automatically call the dispensing program.

5. Visually customize the running track or point-to-point position, and freely program the length, position, speed, height and working status of each XYZ motion track.

6. Fully visual guided programming, programming time is 30%-50% faster than desktop operating systems.

Application field

Various dispensing processes of camera module

Various dispensing processes of screen modules

Cold wire Protective Adhesive

Chip protection adhesive

Flip chip underfill

Conductive silver paste

seal PIN glue

Bracket glue

Components [optional]

Bottom heating module

Bottom Vacuum Module

Dual platform

Low level detection and alarm

AOI detection module

Technical Specification

Send Inquiry

English

English